Overview

Campbell Scientific's Solar Operational Meteorological (Op Met) Monitoring Stations are purpose built to meet the wide range of solar energy monitoring demands. They are designed with ease of operation and maximum data availability in mind. All measurements and parameters pass seamlessly to local Supervisory Control and Data Acquisition (SCADA) systems or on-site and off-site servers. Each station is built to operate beyond the lifetime of the solar energy project.

These stations are customized to meet customer and site-specific requirements. Typical stations measure the following parameters:

- Global Horizontal Irradiance (GHI)

- Plane of Array (POA) irradiance

- Rear POA (RPOA) irradiance

- Diffuse Horizontal Irradiance (DHI)

- Albedo

- Back-of-Module (BOM) temperature

- Ambient air temperature

- Relative humidity

- Wind direction

- Wind speed

- Precipitation

- Barometric pressure

- Soiling ratio or soiling-loss index

- Snow depth (if required)

- Hail

Benefits and Features

- IEC 61724-1:2021-compliant station

- Variants available to additionally meet California ISO or Alberta Electric System Operators (AESO) standards

- Modbus or DNP 3.0 communications to SCADA

- Easy installation using Campbell Scientific mounts

- Rugged design

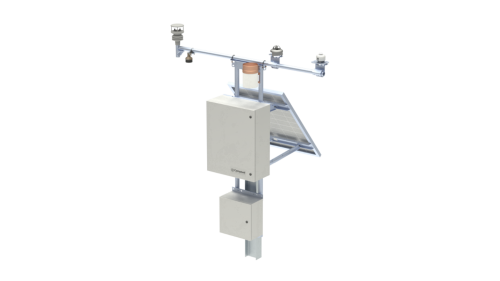

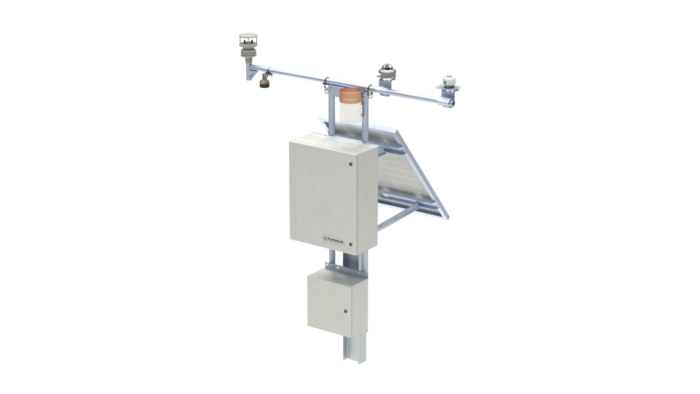

Images

Detailed Description

The Solar Op Met Monitoring Station is designed to meet the IEC 61724-1:2021 requirements for meteorological monitoring for a Class A monitoring system. These systems provide critical data for operational solar power plants.

Rugged Design

As mandated by many independent service operators, solar Op Met stations must minimize station down time and maximize data availability. Campbell Scientific is well known throughout the world for designing and manufacturing weather stations for the most unforgiving environments on Earth. We carefully choose similarly rugged accompanying sensors for use in these multi-decade projects.

Campbell Scientific has designed the station mounting to be compatible with the infrastructure that already exists on most utility-scale solar power plants. The main met station mounts to an I-pile driven identically to the nearest support pile for the solar racking system. Furthermore, stations have been designed to allow for installation by a single individual. See the installation guide and video for more information.

Sensors

Sensors are chosen to meet the requirements of Class A monitoring systems defined by IEC 61724-1:2021 with additional consideration given to operational ease. Campbell Scientific has also paired each sensor with our line of mounts designed for use in the photovoltaic (PV) solar market.

Irradiance

- MS-80SH Class A Fast-Response Pyranometer with lowest measurement uncertainty and an integrated dome heater

- SMP12 Class A Fast-Response Pyranometer with an integrated dome heater

- SR30-L Class A Pyranometer with RS-485 Modbus Communications with Integrated Heating and Ventilation

- DHI measurements with Class A pyranometers on trackers or SPN1 sensors

- Choice of Class A or C pyranometers as well as PV reference cells for RPOA measurements

- Multi-parameter weather sensors for rapid deployment and simple operation

- DustVue Solar-Module Soiling Sensor for PV soiling

Back-of-Module Temperature

The CS241DM is the industry-leading, back-of-module temperature sensor designed for bifacial PV module temperature and PV soiling measurements. The sensor makes use of an optimized, small footprint to reduce back-of-module shading and eliminate surface cooling. Other improvements include greater sensor-to-module bonding/adhesion and a thinner Teflon cable with a higher temperature rating.

Meteorological

The MetSens500 Compact Weather Sensor measures wind speed and direction via an ultrasonic sensor, as well as air temperature, relative humidity, and barometric pressure. This sensor is a single, combined instrument mounted inside three double-louvered, naturally aspirated radiation shields with no moving parts. An integrated electronic compass allows the MetSens500 to provide accurate relative wind direction measurements without a particular orientation, making installation easier.

Factory Acceptance Testing

- All electronic system components provided by Campbell Scientific are configured and tested prior to shipping to the site.

- Calibration sheets are digitized and saved with the system documentation.

- System components are individually labeled to assist with field installation.

- Standard or site-specific Modbus or DNP3 register maps are generated to assist the SCADA integration.

Documents

Privacy Policy Update

We've updated our privacy policy. Learn More

Cookie Consent

Update your cookie preferences. Update Cookie Preferences