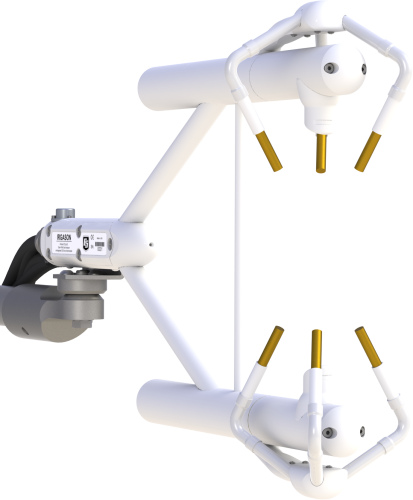

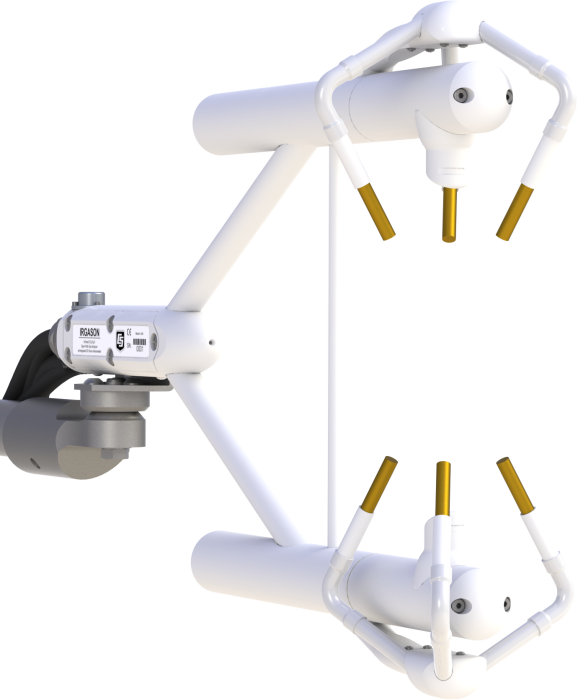

Gas analyzer and sonic anemometer in one sensor

Overview

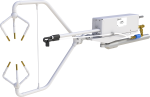

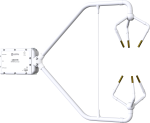

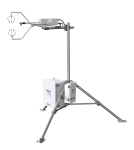

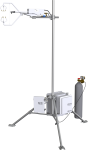

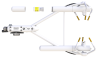

Campbell Scientific’s IRGASON® fully integrates the open-path analyzer and sonic anemometer. Designed specifically for eddy-covariance carbon and water flux measurements, the patented design is easier to install and use than separate sensors and provides increased measurement accuracy. The IRGASON simultaneously measures absolute carbon dioxide and water vapor, air temperature, barometric pressure, three-dimensional wind speed, and sonic air temperature. U.S. patent D680455

For more information about the benefits of having a collocated measurement, refer to the poster "Improved eddy flux measurements by open-path gas analyzer and sonic anemometer co-location."

Read MoreBenefits and Features

- New conformal coating helps protect sonic transducers in corrosive environments

- Combined support structure causes less flow distortion than two separate sensors

- Truly collocated gas analyzer and sonic anemometer measurements avoid flux loss due to sensor separation

- Synchronized gas analyzer and sonic anemometer measurements avoid the need to correct for time lag

- Low power consumption; suitable for solar power applications

- Temperature-compensated measurements without active heat control

- Low noise

- Maximum output rate of 60 Hz with 20 Hz bandwidth

- Angled windows to shed water; tolerant to window contamination

- Field rugged

- Field serviceable

- Factory calibrated over wide range of CO2, H2O, pressure, and temperature in all combinations encountered in practice

- Extensive set of diagnostic parameters

- Fully compatible with Campbell Scientific data loggers; field setup, configuration, and field zero and span can be accomplished directly from data logger

- Sonic temperature determined from three acoustic paths; corrected for crosswind effects

- Innovative signal processing and transducer wicks considerably improve performance of anemometer during precipitation events

Images

Similar Products

Detailed Description

The IRGASON has the following outputs:

- Ux (m/s)

- Uy (m/s)

- Uz (m/s)

- Sonic Temperature (°C)

- Sonic Diagnostic

- CO2 Density (mg/m3)

- H2O Density (g/m3)

- Gas Analyzer Diagnostic

- Ambient Temperature (°C)

- Atmospheric Pressure (kPa)

- CO2 Signal Strength

- H2O Signal Strength

- Source Temperature (°C)

Specifications

| Patent | U.S. Patent No. D680455 |

| Operating Temperature Range | -30° to +50°C |

| Calibrated Pressure Range | 70 to 106 kPa |

| Input Voltage Range | 10 to 16 Vdc |

| Power | 5 W (steady state and power up) at 25°C |

| Measurement Rate | 60 Hz |

| Output Bandwidth | 5, 10, 12.5, or 20 Hz (user-programmable) |

| Output Options | SDM, RS-485, USB, analog (CO2 and H2O only) |

| Auxiliary Inputs | Air temperature and pressure |

| Warranty | 3 years or 17,500 hours of operation (whichever comes first) |

| Cable Length | 3 m (10 ft) from IRGASON to EC100 |

| Weight |

|

Gas Analyzer |

|

| Path Length |

15.37 cm (6.05 in.) A temperature of 20°C and pressure of 101.325 kPa was used to convert mass density to concentration. |

Gas Analyzer - CO2 Performance |

|

| -NOTE- | A temperature of 20°C and pressure of 101.325 kPa was used to convert mass density to concentration. |

| Accuracy |

|

| Precision RMS (maximum) |

0.2 mg/m3 (0.15 μmol/mol) Nominal conditions for precision verification test: 25°C, 86 kPa, 400 μmol/mol CO2, 12°C dewpoint, and 20 Hz bandwidth |

| Calibrated Range | 0 to 1,000 μmol/mol (0 to 3,000 μmol/mol available upon request) |

| Zero Drift with Temperature (maximum) | ±0.55 mg/m3/°C (±0.3 μmol/mol/°C) |

| Gain Drift with Temperature (maximum) | ±0.1% of reading/°C |

| Cross Sensitivity (maximum) | ±1.1 x 10-4 mol CO2/mol H2O |

Gas Analyzer - H2O Performance |

|

| -NOTE- | A temperature of 20°C and pressure of 101.325 kPa was used to convert mass density to concentration. |

| Accuracy |

|

| Precision RMS (maximum) |

0.004 g/m3 (0.006 mmol/mol) Nominal conditions for precision verification test: 25°C, 86 kPa, 400 μmol/mol CO2, 12°C dewpoint, and 20 Hz bandwidth |

| Calibrated Range | 0 to 72 mmol/mol (38°C dewpoint) |

| Zero Drift with Temperature (maximum) | ±0.037 g/m3/°C (±0.05 mmol/mol/°C) |

| Gain Drift with Temperature (maximum) | ±0.3% of reading/°C |

| Cross Sensitivity (maximum) | ±0.1 mol H2O/mol CO2 |

Sonic Anemometer - Accuracy |

|

| -NOTE- | The accuracy specification for the sonic anemometer is for wind speeds < 30 m s-1 and wind angles between ±170°. |

| Offset Error |

|

| Gain Error |

|

| Measurement Precision RMS |

|

| Speed of Sound | Determined from three acoustic paths (corrected for crosswind effects) |

| Rain | Innovative signal processing and transducer wicks considerably improve performance of anemometer during precipitation events |

Basic Barometer (option -BB) |

|

| Total Accuracy |

|

| Measurement Rate | 10 Hz |

Enhanced Barometer (option -EB) |

|

| Manufacturer | Vaisala PTB110 |

| Total Accuracy | ±0.15 kPa (-30° to +50°C) |

| Measurement Rate | 1 Hz |

Ambient Temperature |

|

| Manufacturer | BetaTherm 100K6A1IA |

| Total Accuracy | ±0.15°C (-30° to +50°C) |

Documents

Manuals

Technical Papers

Compliance

Miscellaneous

- Improved Flux Measurements from Campbell Scientific Open-Path Gas Analyzers: Utilizing Sonic Temperature to Account for Spectroscopic Effects on CO2 Density

- High-Frequency Air-Temperature Fluctuations for Spectroscopic Corrections

- Influence of Open-path Gas Analyzer Flow Distortion on Ultrasonic Wind Measurements

- Benefits of Having a Co-Located Measurement

- Using Molecular Sieve to Zero Infrared Gas Analyzers for Eddy Covariance or Atmospheric Profile Measurements

- Qingyuan Project Update

- IRGASON and EC150 Source and Detector Cover Updates

Downloads

EasyFlux DL for CR6OP v.2.02 (99.2 KB) 10-31-2025

CR6 datalogger program for Campbell open-path eddy-covariance systems.

EC100 OS v.8.02 (560 KB) 10-14-2019

EC100 Operating System.

Watch the Video Tutorial: Updating the EC100 Operating System.

ECMon v.1.6 (10.7 MB) 03-29-2016

EC100-Series Support Software.

Device Configuration Utility v.2.33 (49.6 MB) 07-07-2025

A software utility used to download operating systems and set up Campbell Scientific hardware. Also will update PakBus Graph and the Network Planner if they have been installed previously by another Campbell Scientific software package.

Supported Operating Systems:

Windows 11 or 10 (Both 32 and 64 bit)

EasyFlux DL for CR1000XOP v.2.02 (99.2 KB) 10-31-2025

CR1000X datalogger program for Campbell open-path eddy-covariance systems.

Frequently Asked Questions

Number of FAQs related to IRGASON: 22

Expand AllCollapse All

-

Yes. A fine-wire thermocouple, such as a FW05, can be used.

-

The EC150 and IRGASON® gas analyzer windows are polished, slanted at an angle, and coated with a hydrophobic material to prevent water from collecting on their surfaces. Wicks may also be used on the windows to promote capillary action and move water away from the window edges. Also, heaters in the snouts may be turned on to help minimize data loss because of precipitation and condensation events.

-

The IRGASON® has been optimized for most terrestrial applications. If the IRGASON® is to be used in a marine environment or in an environment where it is exposed to corrosive chemicals (for example, sulfur-containing compounds in viticulture), expect the sonic transducers to age more quickly and require replacement sooner than a unit deployed in an inland, chemical-free environment. If possible, mount the IRGASON® in a way that reduces exposure to saltwater spray/splash and/or corrosive chemicals.

-

The factory calibration accounts for CO2 and H2O signal strengths down to 0.7. Therefore, to ensure quality data, windows should be cleaned before signal strengths drop below 0.7.

-

The frequency at which a zero/span should be done is highly dependent on site conditions; however, a monthly zero/span is a good starting point. As a general guideline, monitor the optical drift of the instrument over time to determine how often a zero/span procedure needs to be performed.

-

The barometer and temperature sensor are needed because the IRGASON® and EC150 have been calibrated at the factory over a range of temperatures (-30° to +50°C) and barometric pressures (70 to 106 kPa).

-

EdiRe (University of Edinburgh) and MATLAB (MathWorks) are two of the products eddy-covariance customers have used to post-process their data. Others are also available. (For more information, review the EdiRe technical paper titled “EdiRe Software for Micrometeorological Applications.)

Campbell Scientific’s default data output format is TOB1 binary, which is compatible with most post-processing software packages. If another data format is needed, Campbell Scientific’s LoggerNet software may be used to convert TOB1 to another format.

-

The IRGASON® is an integrated open-path gas analyzer and sonic anemometer, whereas the EC150 is a separate open-path gas analyzer that may be paired with a CSAT3A sonic anemometer. Both instruments provide measurements that are synchronous or simultaneous, made possible by having one set of electronics, the EC100, controlling the execution of both gas and wind measurements. With its integrated design, the IRGASON® is able to make measurements exactly colocated, which means that a spatial correction does not need to be applied to fluxes. Unlike the IRGASON®, the EC150 has measurement volumes that have a small separation, which means a spatial correction must be applied.

For more detailed information, see the white paper “EC150, IRGASON, or EC155: Which CO2 and H2O Eddy-Covariance System Is Best for My Application?”

-

Selecting which barometer to use is the choice of the user. There is a direct correlation between the accuracy level of the barometer and its cost.

- The basic barometer has an accuracy of ±1.5 kPa between 0° and 50°C. Below 0°, the error increases linearly to ±3.7 kPa at -30°C.

- The enhanced barometer offers an accuracy of ±0.15 kPa (-30° to +50°C).

When choosing a barometer, consider the effect of pressure accuracy on flux calculations. For sensible heat flux, the barometric pressure is used to calculate the density of air, which directly scales the sensible heat flux. Therefore, if the barometric pressure measurement is off by 1%, then the sensible heat flux will be off by 1%.

For CO2 flux, the EC150 and IRGASON® report CO2 as density. Thus, the barometric pressure is not used to directly calculate the flux. However, error in pressure measurements could cause an error in CO2 flux resulting from a CO2 span. During the span procedure, the user enters the “true CO2 value” as a CO2 concentration, which is later converted to density using the barometric pressure. Consequently, the error in CO2 measurements is directly proportional to the error in the barometric pressure measurement.

-

For greatest accuracy, Campbell Scientific recommends that a zero and a span be done on the EC150 or IRGASON®. However, if a span gas is difficult to obtain, at the minimum, perform a zero on the analyzer. Performing a zero will correct the majority of drift experienced by the analyzer. Follow the zero procedure in the analyzer’s manual for details.

Case Studies

Understanding the spatial variability of the Earth’s atmospheric boundary layer—including the surface layer near the......read more

Overview In the fight against climate change, innovative solutions are emerging to address the global challenge......read more

The Utah Geological Survey, supported by the Utah Division of Water Rights, has constructed a......read more

The Wolf Creek Dam near Jamestown, Kentucky, was constructed partially as a regular concrete hydroelectric......read more

Articles and Press Releases

Privacy Policy Update

We've updated our privacy policy. Learn More

Cookie Consent

Update your cookie preferences. Update Cookie Preferences